solving a problem

The main challenges that the honey industry will face in the future are:

Bee disease

Climate Change

Health Food Trends

Swarming and Foraging

The main consequence that run through these challenges is low honey production. To address this issue, added-value products are the most effective way to double exports as it maximises the value of the limited honey quantities. Through various idea generation and screening processes, a final integrated idea had been selected. The final idea is a new form of food packaging using a byproduct of honey production- beeswax. This combines the chemistry aspects of a beeswax oil, using beeswax as a preservative, and using beeswax as packaging. This integrated solution addresses three of these four issues: Climate change, health food trends and swarming and foraging.

Making use of waste product

Beeswax is currently a waste product of honey production, and is not fully utilised. The honeycomb is cut off and thrown away during honey harvesting. Turning a waste product into an added value product will bring more profit to the beekeepers, without a huge amount of financial investment. The money spent to get rid of the beeswax is now used to further develop it into a marketable product, bringing more profit.

The cost of the produce would be very low, with a relatively large margin of profit, as there is a novelty to the product due to its added-value nature. This will contribute greatly to achieving the brief of doubling food and beverage export value.

Avoiding Consequences of Climate Change

Changes in climate can have serious effects on honey production. Being able to take advantage of an alternate source of resources when honey production volume becomes undependable. Beeswax production is not affected by the changing climate so a steady production of beeswax is guaranteed.

Heading towards a plastic free world

This product also fits in with the healthy, environmentally- friendly consumer trend that is taking the world by storm. The use of plastic is now being discouraged due to its negative environmental impact. The beeswax packaging is an environmentally friendly alternative to plastic packaging. Not only is it good for the environment, but the beeswax can also be reused. This reduces the amount of plastic-free waste in the world which is attract to the new generation of consumers.

Beeswrap

With the existence of beeswax food wraps in the market as an eco-friendly alternative to plastic, and because it holds homemade DIY potential, this is an area of marketing in which the final idea developed must be innovative, creative and simple enough to stand out. Thus, a liquid, straight-contact food wrap idea was born.

How to Use

To use the product, the contents must be melted into a liquid for approximately 5 minutes in a 1100W microwave. The half-eaten food would be briefly dipped into the solution, enough to coat it and it dries all on its own. Due to its antibacterial active properties, it is capable of inhibiting the spread of food-borne bacterial pathogens, as well as contribute to preventing food spoilage therefore preserving the food it coats. Because of this, it is unable to be contaminated as it can be washed and reused. If the food is not able to be dipped, by pouring a small amount of the solution onto a hard surface where it will spread thin and harden, it will act as a cling film wrap that will cover the food and preserve it in the same manner. If the food were to be reheated for consumption, the beeswax must be removed due to its low melting point.

Once the packaging is no longer needed on the food, it will be easily removed by peeling it off the food. It then is easy to clean using cold water and dishwashing liquid where once it is cleaned could be melted back into the container with the remaining solution. It is important to run the beeswax under cold water to ensure that the beeswax is not completely in liquid form and its antibacterial properties are not compromised.

If the remaining solution after multiple uses is not enough to be used, it can be repurposed by melting into a candle or shoe shine wax. Therefore this solution will have all of its contents purposed, minimising the amount of waste produced.

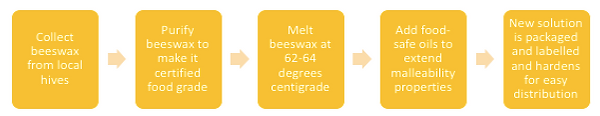

How it is made

This product requires food grade beeswax (fresh or pellets) to be melted down at 62-64oC into a liquid form. Anything from 85oC or higher will discolour and destroy the beeswax and be unusable. It will then be mixed with oil or some food safe lubricant such as jojoba oil that will allow the beeswax to be malleable, to release the food when peeled in one piece rather than cracking and breaking the seal. The new solution is now kept in its new packaging in which it will harden and solidify. Future testing is required to determine the ratio between beeswax and oil.

"Beeswrap" would be sold in glass jars with correct and legal labelling and design.

TIMELINE

TIMELINE

-

reaserch into beeswax.

2019

-

Design the product.

-

develop by testing.

2020

-

finish product.

-

apply paTents to protect idea.

2021

-

design the packaging.

-

begin marketing.

-

low scale manufacture.

2022

-

collect the feedback and improve.

-

work out retail points.

2023

-

large scale manufacture.

-

local advertising.

-

local selling.

2024

-

overseas marketing.

-

export logistics paperwork.

2025

-

begin export.

-

online store establishment.

-

advertising internationally.

2026

-

retail outlets establishment.

2027

-

export doubled!

2028